Component

Component

Handsfree Door Openers from Protomould Plastics

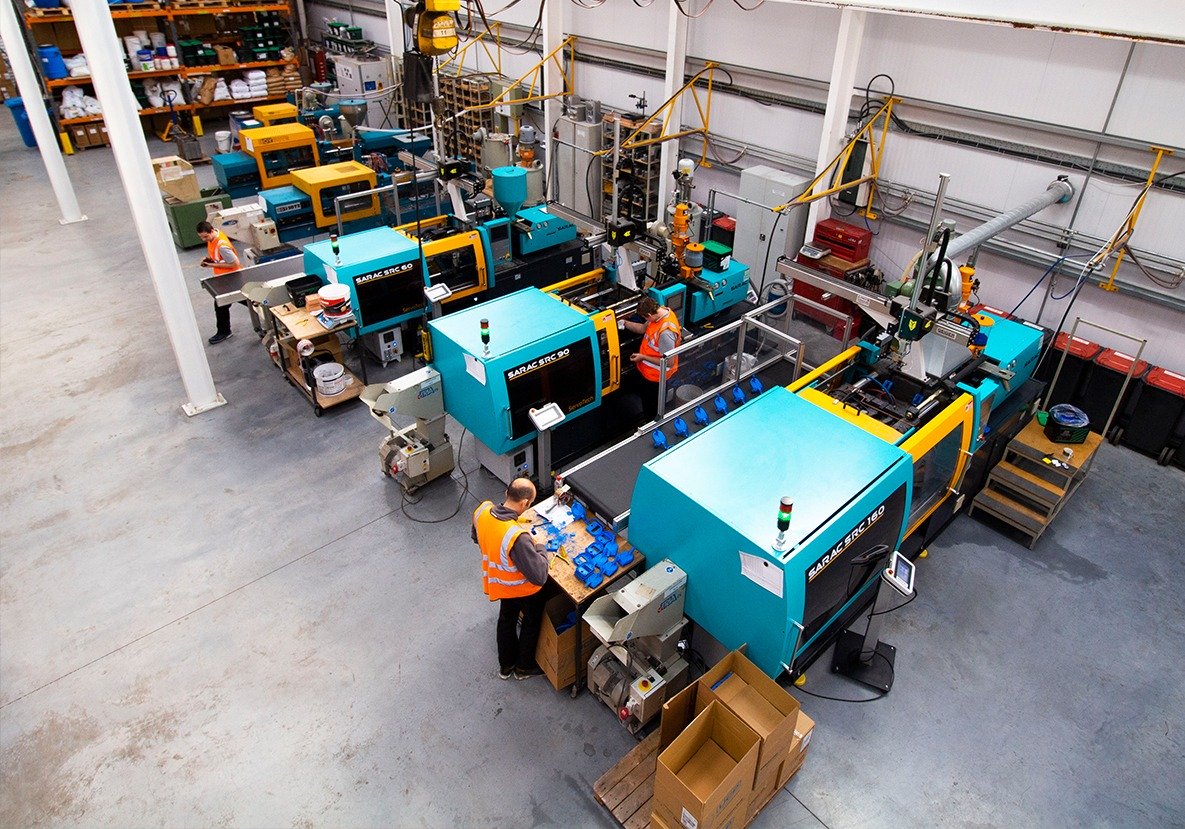

Known for being a high-quality plastic moulding manufacturer in Hull, we recently commissioned a new factory in East Yorkshire allowing us to expand our capabilities with new injection moulding machinery. We specialise in plastic injection moulding, and have been able to use our industry skills to produce a new product – our hands-free door opener.

Read more